Innovative Vision Detection System

Benefits

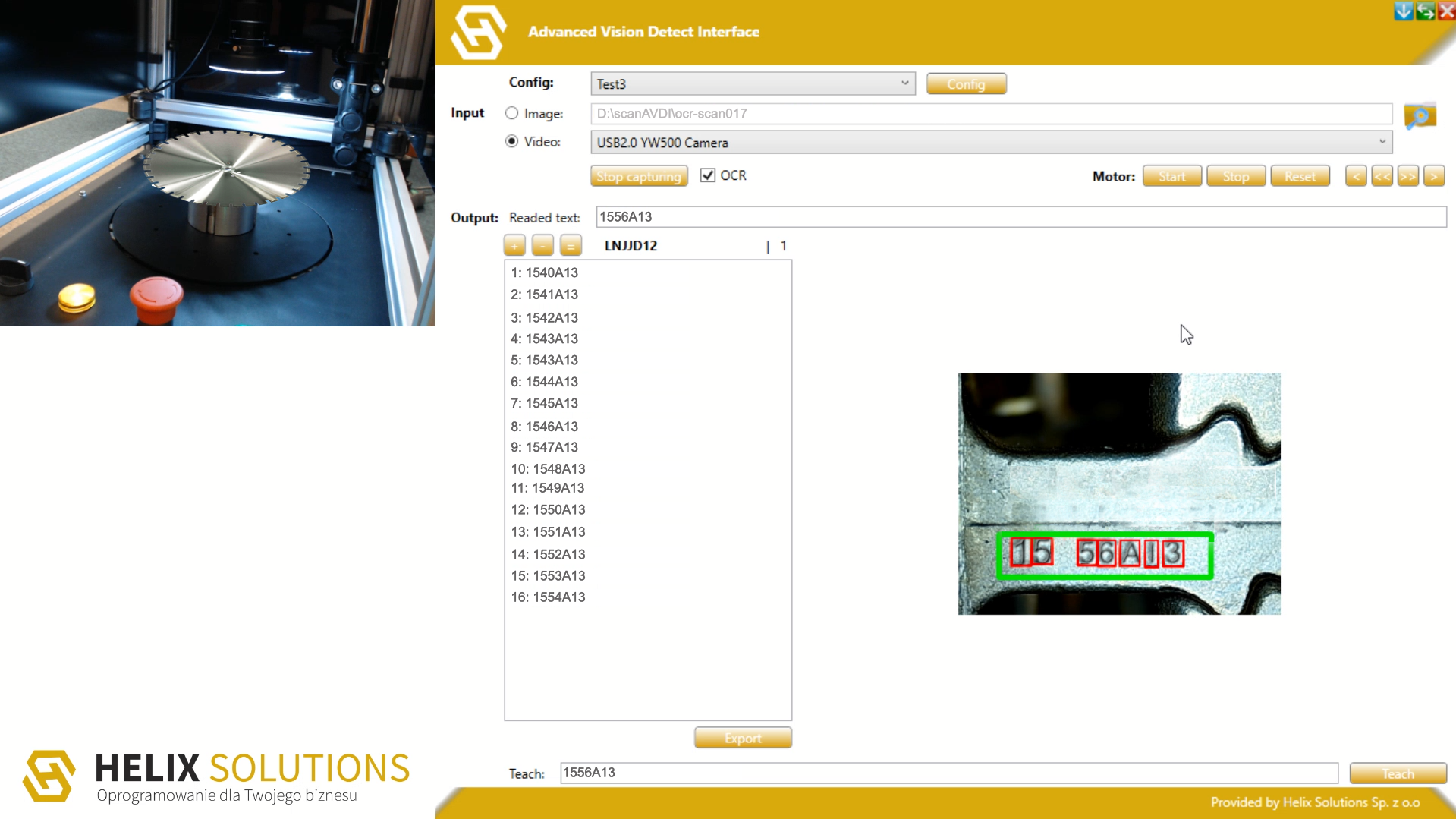

Process Automation

The system automatically performs repetitive and monotonous tasks for employees while maintaining the highest quality and precision in data reading.

Precision and Speed of Data Reading

The collected information is automatically saved to the database without the need to stop the production line, ensuring continuity of operations.

Component Identification

Ensuring individual control of each component and detecting defects at the earliest stage of production leads to better resource utilization, as well as high quality and efficiency in production.

Damage Diagnostics

The device is capable of detecting the smallest defects in individual components without interrupting the workflow or halting the production line.

Minimized Risk of Error

By installing the vision detection system, the risk of using or releasing an unmarked or incorrectly labeled component is eliminated.

Increased Customer Trust

Defect detection and the elimination of products with incorrectly marked components minimize the risk of defective products reaching customers, contributing to safety and increased customer satisfaction.